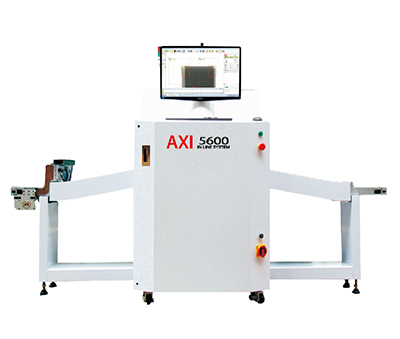

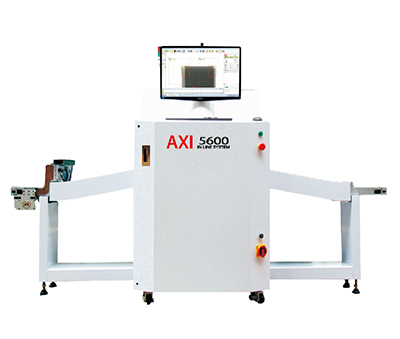

Fully automatic online detection equipment

The newly upgraded American Shansi AXI5600 adopts a retractable synchronous roller structure, which can compact the soft pack and accurately achieve diagonal boundary testing without touching the boundary of the soft pack battery. Non-stop conveyor belt shooting and fully automatic loading and unloading structure ensure high testing productivity and stability.

Use the conveyor belt method and complete the image capture in one go.

There will be no distortion in the image regardless of the thickness of the battery.

There is no need to use a robot to alternately feed materials.

Automatically determine good and defective products, and automatically sort defective products.

To detect different types of batteries, there is no need to change fixtures or debug.

It can be connected to the production line for high-speed detection, and can automatically determine the alignment of the positive and negative poles, maximum and minimum values.

*Retractable synchronous roller structure | *Automatic measurement |

*Automatic measurement | *Automatic measurement

|

Shenzhen Topco Electronics Co., Ltd. specializes in providing the following SMT equipment to electronic manufacturers:

MPM printing press , Koh Young SPI

Panasonic placement machine , Fuji placement machine , Siemens placement machine

Meilu AOI , Vitronics Soltec reflow soldering

The entire SMT production line equipment, as well as spare parts, services and solutions.

135 1032 1270

Contact: Miss Jiang

Mail box: market@topsmt.com

Address: 201, Building 4, Innovation Port, Hanyu Bay, Fuhai Street, Baoan District, Shenzhen